Abstract

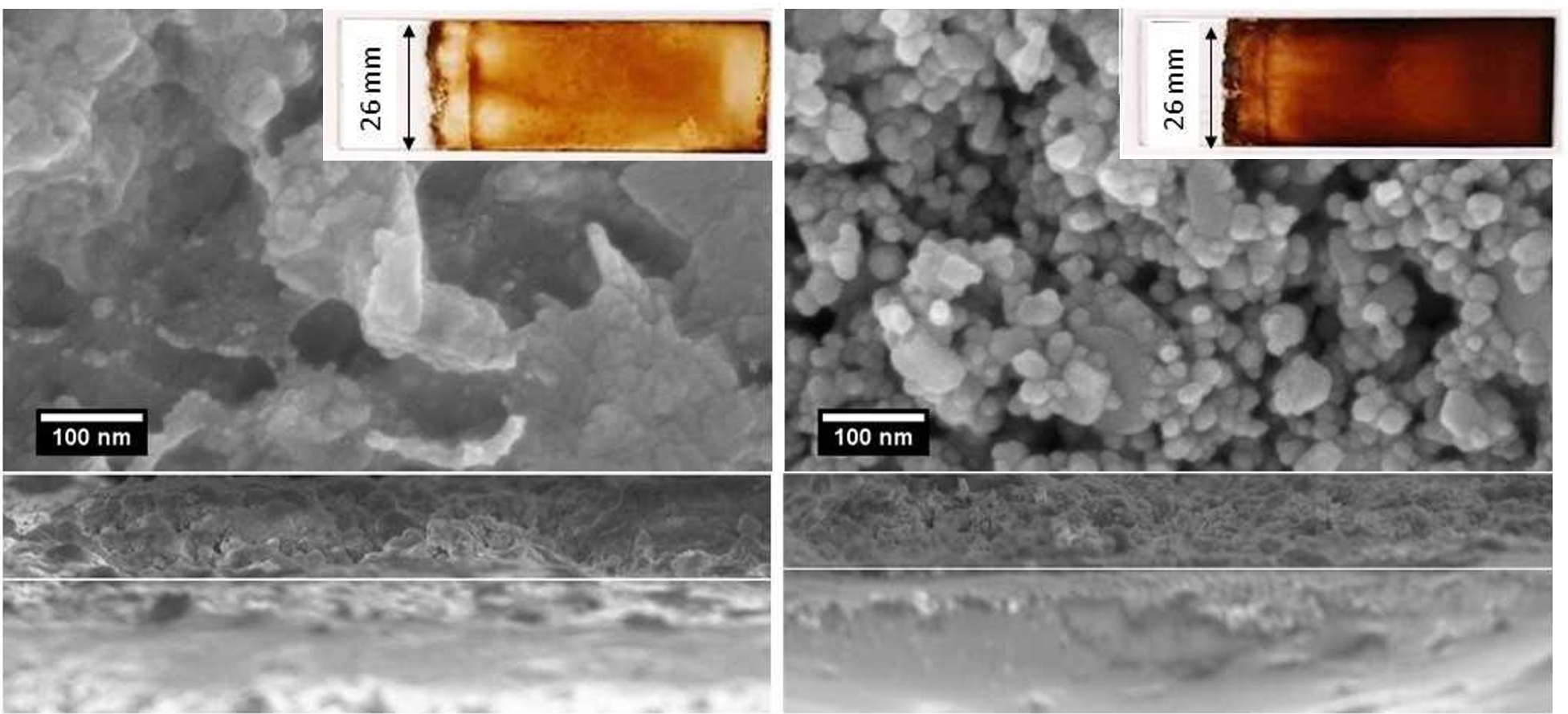

In this work, we present the design, fabrication, and automation of a customized and affordable system capable of performing the thin film deposition techniques of Dip-Coating and SILAR at room temperature. To automate the system, parts from disused equipment were reused, new pieces were fabricated through additive manufacturing, and open-source software was also utilized. The device was controlled using an Arduino UNO R3. Additionally, graphical interface was developed in Python with the PyQt library to adjust the motion settings and transmit parameters to the Arduino via serial communication. We validated the system by fabricating layers of Cu2O and CuO, subsequently comparing their structural and morphological properties with findings previously reported in the literature.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright (c) 2024 Cuban Physical Society & Faculty of Physics of the University of Havana